Cut-To-Size Fabrication

The Purpose and Benefit Of The Fabrication Facility

“Cut virtually any material, from modern natural stones to highly engineered materials”

With the newly developed world class fabrication facility our purpose is dedicated to efficiently execute cut-to-size projects meticulously and under an expedited timeframes (1 CONTAINER PER DAY)..

Getting Started

We strive to achieve each customer’s requirement by understanding their own goals and correspondingly incorporating them with our experience and expertise.

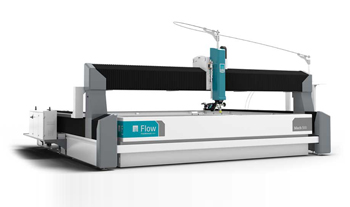

Undertaking vast and large scale projects in the past, the four latest additions of (GMM’S BRIO CN2 BRIDGE SAW, GMM TORO 62 EDGE POLISHER & FLOW’S MACH 300 WATER-JET), will provide us with eased increased productivity and capacity.

Moreover, it will contribute to an extended support in delivering precise finished goods to a fine degree, all the while ensuring Cost Effective options.

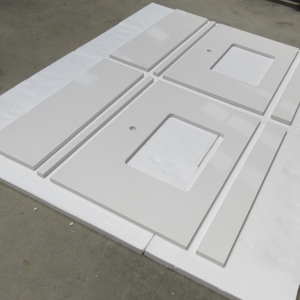

Throughout the process, our team will assist you in every direction, from our TWENTY MEMBER POLISHING TEAM our on the ground PRODUCTION OPERATORS and FOUR IN HOUSE CAD ENGINEERS (Creation/ Conversions of CAD PDF Files/Templates) – all leading to an automatic feed to the machines Being thorough and precise is what drives the company. Chariot particularly focuses on the finishing in its quality and systems to deliver categorical products. It uses the best machines and processes including: GMM CNC Bridge-Saws to cut and profile any design, GMM Edge Profiling Polishers to enhance the gloss of products, flow water-Jets for precision cutting, a 40-member sink hand-polishing team, thorough inspections and more. These systems allow for executing three to five containers full for export in one week. Chariot is also the only company that has perfected the 45- degree mitre edge cut on porcelain countertops. For material sourcing, Chariot set up facilities and partnerships with equity investments that are close to the quarries to reduce transportation, and it also has an in-house granite plant.

Chariot strives to provide value for money spent, and it supports an open, transparent approach. The company aims to provide moderately low pricing and to clearly communicate from the point of raw material stage to packing to shipping.

GMM BRIO 35 CN2

- 1 CONTAINER PER DAY

- AUTOMATIZED CAD SMART PROGRAMMING

- MAXIMIZES PRODUCTIVITY SPEED

- THICKNESS / ANGLE TOLERANCE READER

- HYDRAULIC TILTING TABLE

FLOW MACH 300 WATERJET

- FLOW WATER-JET- 1 CONTAINER PER EVERY 2 DAYS PRODUCTION

- AUTOMATED INTERFACE PROGRAMMING

- RAPID SPEED UP TO - 472 in/min

- LINEAR ACCURACY - ± 0.0021 in/3 ft

- RELIABILITY & REPEATABILITY - 0.0014 in

- NO HEAT STRESS ON MATERIAL

GMM TORO 62 EDGE POLISHER

- CAPACITY 1 – CONTAINER PER DAY

- EXTENSIVE SPINDLES FOR MULTIPLE MOVEMENTS

- MULTI-FUNCITION CALIBRATORS

- RELIABILITY & REPEATABILITY

- HYDRAULIC OSCILLATING BAR – MULTIPLE PROFILES

PLEASE CONTACT US WITH YOUR INQUIRIES / DRAWINGS / JOBS AND WE WILL TAKE CARE OF ALL

ADD CONTACT DETAILS

Our Factory

Inspection

Porcelain Cutting

PLEASE CONTACT US WITH YOUR INQUIRIES / DRAWINGS / JOBS AND WE WILL TAKE CARE OF ALL

ADD CONTACT DETAILS

Contact Us

Get in touch with us

- Chariot International Factory

- No.97, Chudagondanahalli Village,

Malur-Hosur Main Road, Malur Taluk,

Kolar District Bangalore – 563130 INDIA. - +91 81 522-88-900 UNTIL 908

- +91-81-522-88-909

-

+91 9845052989 (Sandeep Wadhwa)

+91 9845052989 (Sandeep Wadhwa) -

sandeep@chariotinternational.com

sandeep@chariotinternational.com -

sandeep.wadhwa

sandeep.wadhwa -

+91 9611586070 (Kristopher Jordan)

+91 9611586070 (Kristopher Jordan) -

kris@chariotinternational.com

kris@chariotinternational.com -

chariotjordan11

chariotjordan11

© 2024 Chariot International. All rights reserved.